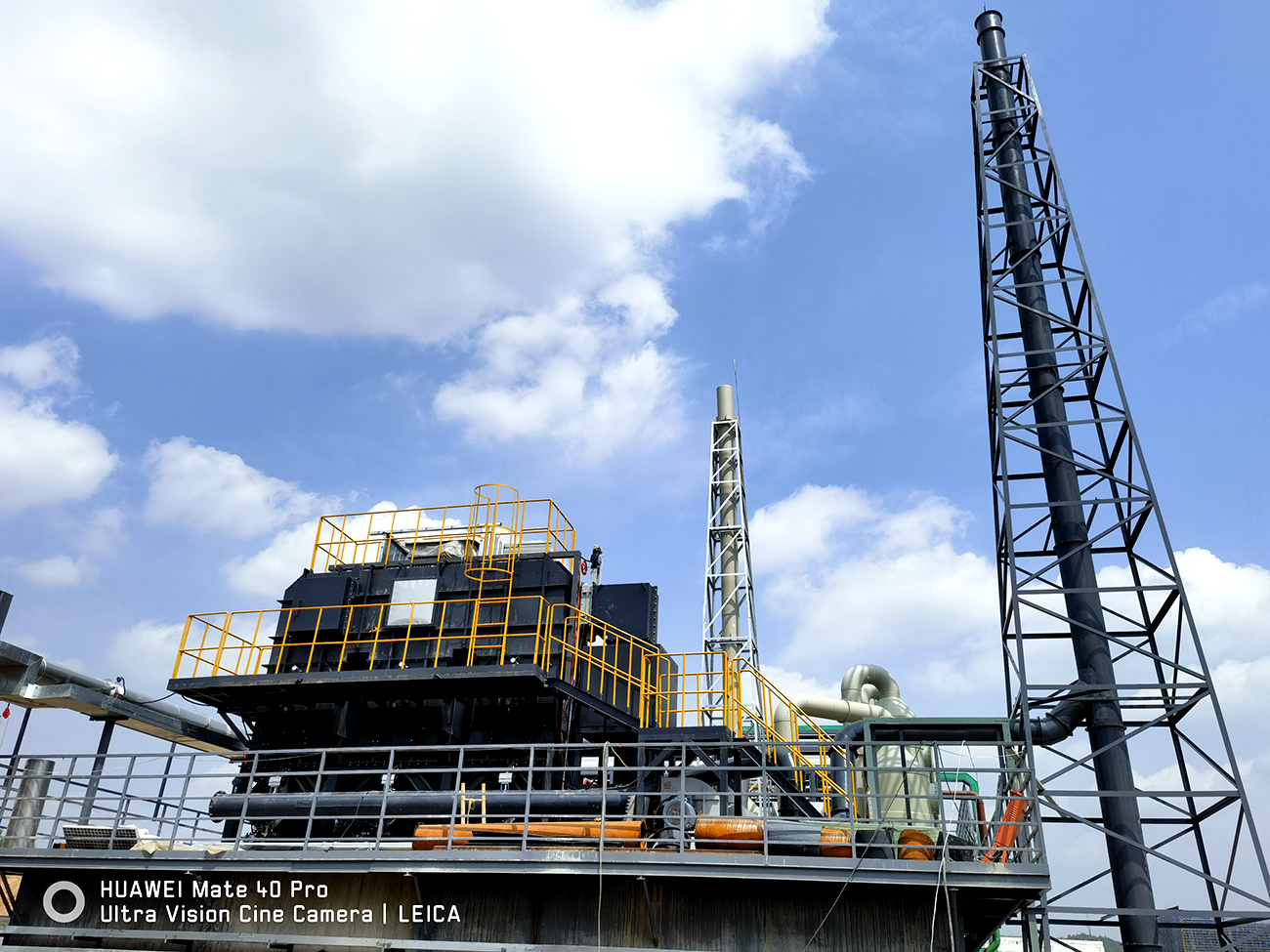

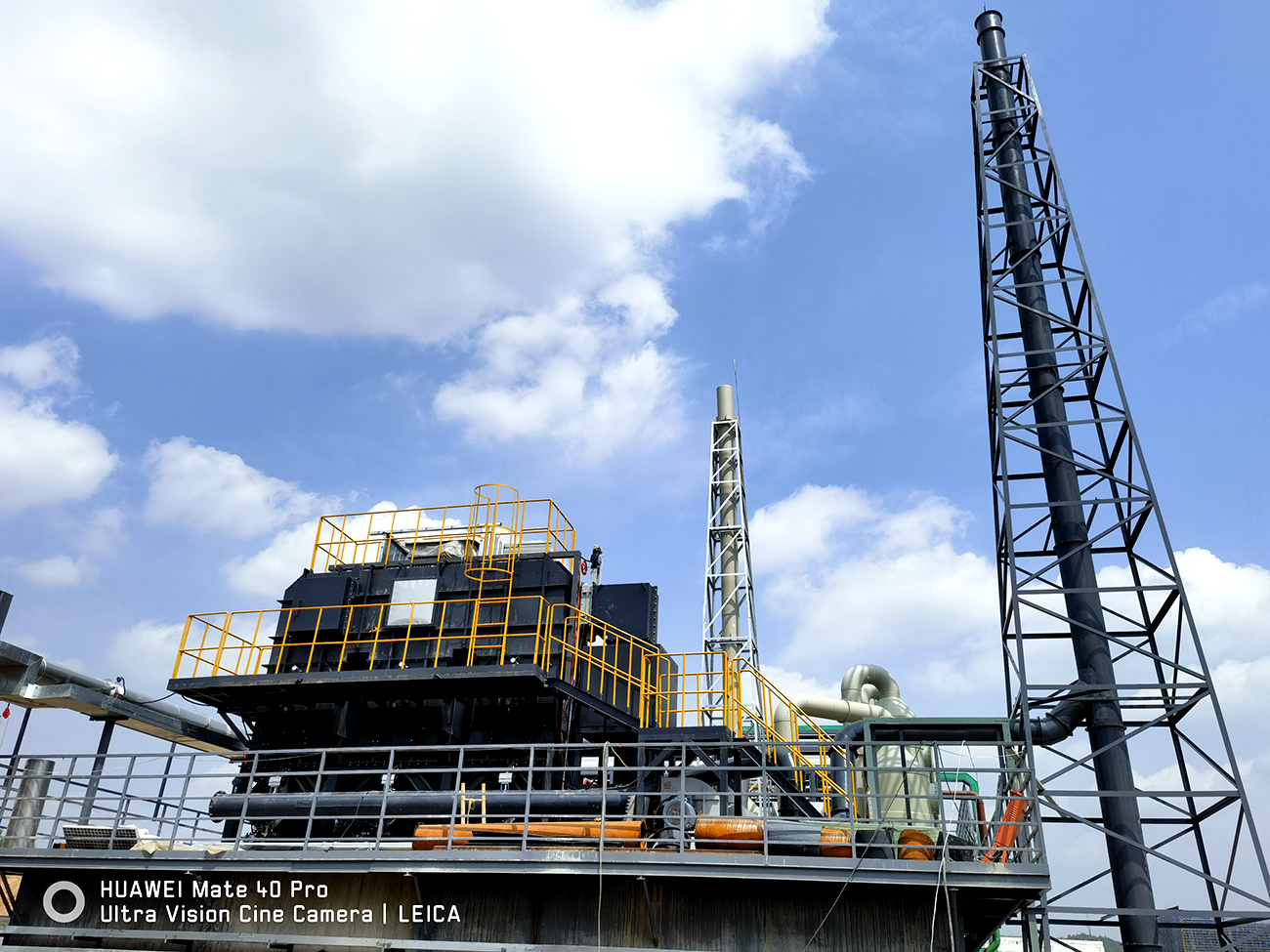

Products Description

The VOC zeolite concentrating rotor uses the three continuous temperature-changing adsorption and desorption procedures of “adsorption-desorption-cooling”. The VOCs waste gas is adsorbed by the rotor and the production process of the rotor is completed at the same time. The useful waste gas entering the concentrating rotor is directly discharged into the atmosphere through the chimney after being purified by zeolite adsorption. The adsorbed useful substances enter the desorption zone due to the continuous rotation of the rotor (1-6 revolutions per hour). The heated gas is used to desorb in this area, so that the low-concentration, high-volume useful waste gas is concentrated into a concentrated gas with good concentration and small flow, and enters the thermal storage incineration device for combustion and conversion into carbon dioxide and water vapor to be discharged into the atmosphere. This cycle continues.

Product features of VOC zeolite concentrating rotor:

1. High adsorption and desorption efficiency, which converts the original high-volume, low-concentration VOCs waste gas into low-volume, high-concentration waste gas, reducing the cost of the back-end final treatment equipment.

2. The pressure drop generated by the zeolite rotor adsorbing VOCs can effectively reduce power consumption. 3. The concentration multiple reaches 3-15 times, which can effectively reduce the specifications of the post-processing equipment and has a relatively low operating cost.

4. The overall system adopts pre-assembly and modular design, has a small space requirement, and provides a continuous and unmanned control mode. 5. The exhaust gas after the rotor concentration can meet the home emission standards.

6. Continuous operation with high safety. Since the core material is molecular sieve, it is highly inert. For VOCs with thermal polymerization such as styrene and cyclohexanone that are difficult to treat with activated carbon, hydrophobic molecular sieves can also be used to efficiently treat them.

Application scope of VOC zeolite concentration rotor:

1. Exhaust treatment of various paint shops.

2. Exhaust treatment of various printing workshops.

3. Exhaust treatment of dry laminated paper products and coating processes.

4. Exhaust treatment of various electronic products manufacturing processes.

5. Exhaust treatment of semiconductor integrated circuit manufacturing processes.

6. Exhaust treatment of liquid crystal display (LCD) manufacturing processes.

7. Exhaust treatment of lithium-ion battery manufacturing processes.

8. Exhaust treatment of fume hoods in large research facilities.

Tags:

Technical parameter

VOC zeolite concentrating rotor 1

产品 2 参数